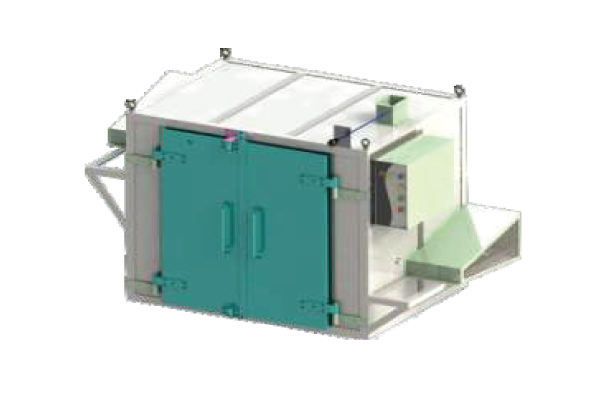

Tray Drier

Tray Drier for efficient moisture removal using forced convection heating, ideal for drying solids in trays with uniform heat distribution.

| Model | UTD-48 | UTD-96 | UTD-192 |

|---|---|---|---|

| No. of Trays / Trolley | 48 / 1 | 96 / 2 | 192 / 4 |

| Workspace (W x D x H) | 40” x 36” x 72” | 77” x 36” x 72” | 77” x 72” x 72” |

| Heating Load | 9 KW | 18 KW | 42 KW |

| No. of Blowers (Axial) | 2 Nos. | 2 Nos. | 4 Nos. |

| Doors | Single | Double | Double |

| Motor for Blower | 1 HP, 1440 rpm, Foot Mounted | ||

| Electric Supply | 415 VAC, 3 Phase, 50 Hz | ||

| Tray Dimension | 32” x 16” x 1.25” | ||

| Control Panel | Automated Digital Control Panel | ||

| Heater | Tubular GI Finned | ||

| Maximum Temperature | 100 °C | ||

| Insulation | 3” thick Rockwool | ||

| MOC – Body | S.S. / M.S. (As required) | ||

| MOC – Trolley | S.S. / M.S. (As required) | ||

| MOC – Trays | S.S. / M.S. / Aluminium (As required) | ||

Description

The Tray Drier is an insulated chamber that utilizes forced convection to remove moisture from solids placed in trays. Hot air is continuously circulated within the chamber, and trolleys carrying trays are moved inside for drying. Electrical heating elements generate heat and automatically shut off once the desired temperature is reached. Designed with a maximum temperature of 100 °C, a 3″ thick Rockwool insulation, and robust construction in stainless steel or mild steel, the Tray Drier ensures uniform drying and energy efficiency. Automated digital control panels enable precise temperature regulation, making it suitable for industrial drying applications.

Reviews

There are no reviews yet.