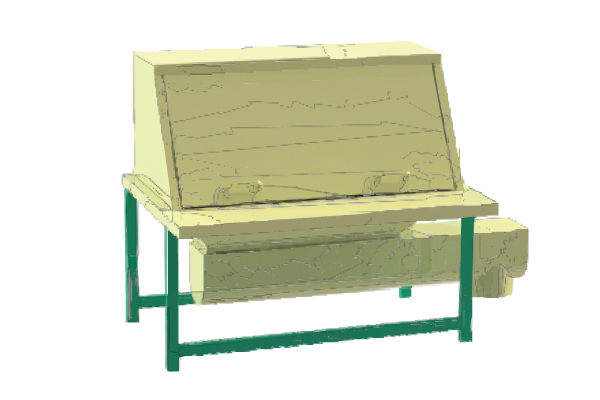

Dumpbooth

A manually operated Bag Dump Station (also known as Dump Booth) designed for safe and dust-controlled introduction of bulk powders or granules into processing lines, commonly used in the food, chemical, pharmaceutical, and powder-processing industries.

| Component | Specification |

|---|---|

| Bag Loading Shelf | Elevated ergonomic grate or shelf for safe emptying |

| Dust Extraction | Built-in downdraft airflow with cyclone or cartridge filter |

| Construction Material | SS (food grade) or PU-painted carbon steel |

| Capacity | Handles manual dumping of individual bags (up to ~50 kg) |

| Filtration | Multistage—prefilter, fine filter, HEPA/cartridge |

| Ergonomics | Raised stainless work surface, easy-clean corners, optional automation with dual dump stations |

Description

The Dump Booth provides a dust-tight, ergonomic workstation where operators manually empty bags into a hopper or grate. The design features downward airflow and internal filtration to capture airborne dust, protecting both personnel and the environment. Typically made from stainless or carbon steel, these stations ensure product integrity and cleanliness. They support modular configurations like dual inlets, optional cyclone or cartridge dust collectors, and food-grade finishes. Ergonomic features include elevated work decks, built-in dust extraction, and easy-clean interiors. Common options include explosion-proof equipment, integrated vibrators or fluidizers, and a removable grate or shelf beneath the bag inlet to facilitate safe dumping.

Reviews

There are no reviews yet.