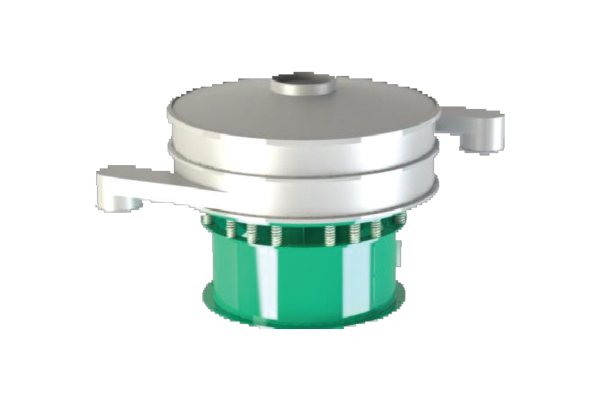

Rotary Sieve

High-capacity rotary sieve for efficient screening, grading, and separation of powders and granules with continuous, dust-free operation.

| Attribute | Specification |

|---|---|

| Screen Diameter | 300 mm – 2000 mm (customizable) |

| Mesh Size | 0.2 mm – 20 mm (application-based) |

| Capacity | 50 kg/hr – 5 tons/hr (depends on material) |

| Construction Material | Mild Steel, SS304/SS316 (food & pharma grade) |

| Drive System | Electric motor with gear reducer, variable speed |

| Applications | Food, chemical, pharma, agro & mineral screening |

Description

A rotary sieve is a cylindrical screening device used for separating and grading powders, granules, and bulk solids by particle size. The rotating drum, fitted with wire mesh or perforated screens, ensures consistent material flow and efficient separation of oversize and undersize fractions. Its gentle tumbling action minimizes product degradation while maximizing throughput.

Material is fed into the rotating drum, where centrifugal and gravity forces move it along the screen’s surface. Oversized particles are discharged at one end, while fine material passes through the screen mesh for collection. The enclosed design reduces dust and contamination, making it suitable for applications in food, pharmaceuticals, chemicals, and agro-processing industries.

Rotary sieves are valued for their low maintenance, easy screen change, and reliable performance in continuous operations.

Reviews

There are no reviews yet.