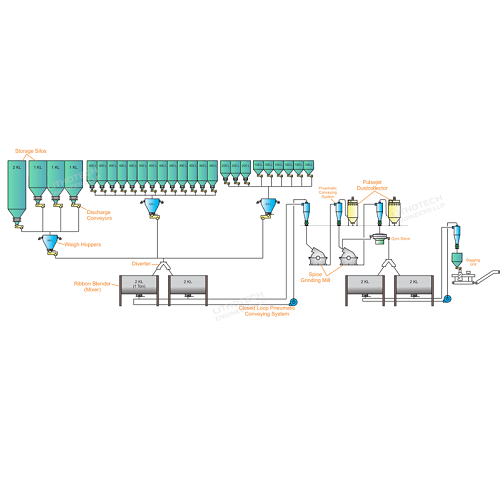

Batching System

Automated Batching System for precise mixing of multiple ingredients with integrated weighing, conveying, and bagging solutions.

| Component | Specification | Quantity |

|---|---|---|

| Silo | 1 Ton, mounted on load cell for weight measurement | 1 Unit |

| Vibratory Feeder | Feeds material from silo to Z-type elevator | 1 Unit |

| Z-Type Elevator | Conveys material to mixers via Y-diverter | 1 Unit |

| Y-Diverter | Pneumatically operated, feeds 2 mixers alternately | 1 Unit |

| Mixers | Twin 750 kg capacity, 10 HP motor, pneumatic flap valve | 2 Units |

| Collection Hopper | 1 Ton capacity, collects discharge from mixers | 1 Unit |

| Screw Conveyor | Transfers material to bagging station | 1 Unit |

| Bagging Station | Dual outlet, automatic 50 kg weighing, manual bag change | 1 Unit |

Description

The Batching System is designed for precise mixing of multiple ingredients according to pre-defined proportions. The process begins with a 1-ton silo mounted on a load cell to ensure accurate weight measurement. Materials are dispensed through vibratory feeders into a Z-type elevator, which transports them via a pneumatic Y-diverter to twin 750 kg mixers. After thorough mixing, the product is discharged into a 1-ton collection hopper, transferred by a screw conveyor, and filled into 50 kg bags at a dual-outlet bagging station. This efficient design ensures continuous, accurate batching with minimal manual intervention and consistent product quality.

Reviews

There are no reviews yet.