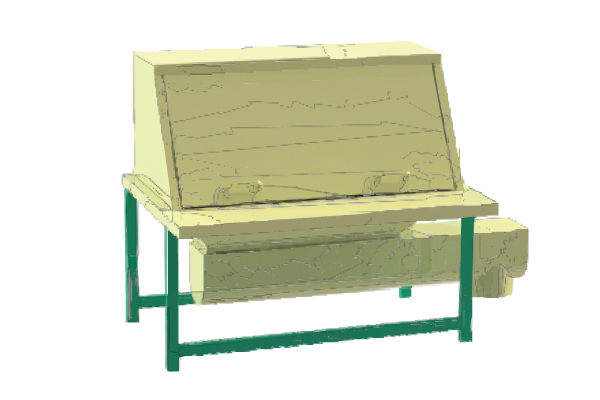

Belt Conveyor

A belt conveyor provides continuous, efficient, and smooth transport of bulk materials or packaged goods across short and long distances, widely used in industrial, food, and logistics applications.

| Attribute | Specification |

|---|---|

| Belt Width | 300 mm to 2000 mm (customizable) |

| Conveying Speed | 0.1 m/s to 3 m/s (variable) |

| Capacity | 50 kg/hr to 200 tons/hr (material & belt size dependent) |

| Incline Angle | 0° to 30° (standard); cleated belts up to 45° |

| Drive Power | 0.5 HP to 20 HP, geared motor drive |

| Construction Material | Mild Steel, SS304/316 for food-grade |

| Optional Features | Cleated belts, mobile frames, covers, and speed controls |

Description

A belt conveyor is a simple yet highly efficient material-handling system that uses an endless belt looped over pulleys to move bulk materials or discrete items from one point to another. The belt, made from rubber, PVC, fabric, or modular plastic, runs on idlers or a flat slider bed and is powered by an electric motor through a drive pulley.

It is suitable for horizontal, inclined, or even curved conveying, offering gentle handling for fragile materials. Capacities and speeds can be customized by adjusting belt width, length, and drive power. The enclosed design minimizes spillage and dust, making it ideal for food, chemical, mining, and packaging industries. Options include mobile or fixed versions, cleated belts for steep inclines, and stainless-steel construction for hygienic operations.

Reviews

There are no reviews yet.